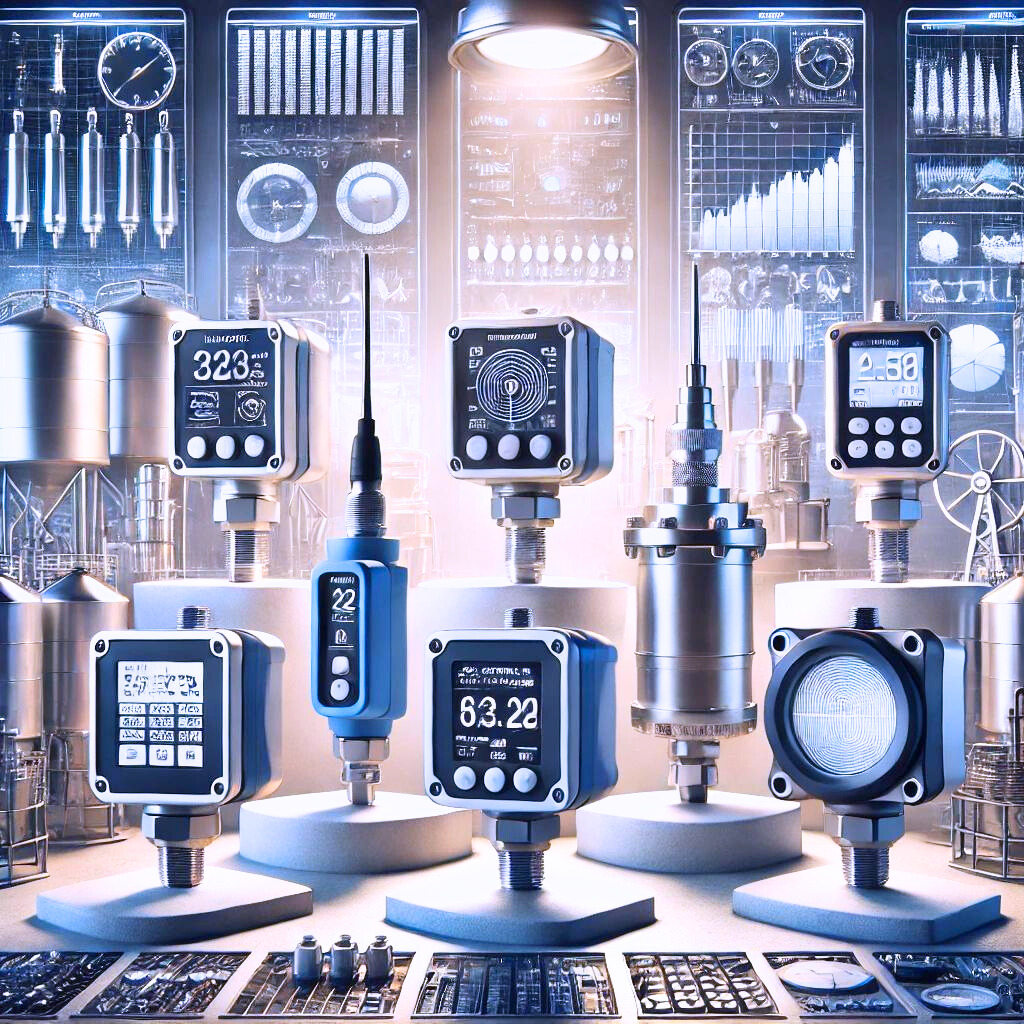

Level Transmitters-insights & types

Level transmitters are pivotal instruments utilized across different industries to gauge the degree of liquids, solids, or gases in tanks and vessels. They provide precise, continuous information, empowering proficient process control and management. In this blog, we will explore the various types of level transmitters, their applications, and how to choose the right one for your specific needs.

What is a Level Transmitter?

A level transmitter is a device that continuously monitors the level of a substance—liquid, powder, or gas—in a container. This data is transformed into signals that can be read by a control system, allowing operators to maintain optimal levels. These instruments are fundamental for applications in industries such as oil and gas, water treatment, food and beverage, and pharmaceuticals.

Types of Level Transmitters

There are several types of level transmitters, each designed to handle specific measurement challenges. Here are the most well-known types:

1. Ultrasonic Level Transmitters

Ultrasonic level transmitters utilize sound waves to measure the level of liquids. The transmitter emits ultrasonic pulses, which reflect back from the surface of the material to the sensor, calculating the distance based on the time it takes for the echo to return. These transmitters are ideal for non-contact measurement, especially in water and wastewater applications.

2. Radar Level Transmitters

Radar level transmitters use microwave radar signals to determine the level of a substance. These transmitters are highly accurate and can measure both liquids and solids in challenging conditions, such as high temperatures, pressures, or dust.

3. Capacitance Level Transmitters

Capacitance level transmitters measure the level based on changes in capacitance between the transmitter probe and the tank wall. They are used for a wide range of applications, including detecting levels of liquids, granular materials, and slurries.

4. Magnetic Level Transmitters

Magnetic level transmitters operate using a float system that contains a magnetic element. As the float moves with the fluid level, it activates a sensor to provide a continuous level measurement. These are often used in industrial environments where direct contact measurement is preferred.

5. Hydrostatic Level Transmitters

Hydrostatic level transmitters use the fluid’s pressure at a certain depth to determine the level. They are popular in water management, chemical storage, and fuel level measurement due to their simple and cost-effective design.

6. Guided Wave Radar Level Transmitters

Guided wave radar level transmitters use microwave pulses guided along a probe to measure the level. They are highly precise and can measure liquids, slurries, and solids in challenging process conditions.

Important Uses of Level Transmitters

Level transmitters are used in various industries to ensure accurate and dependable measurements. Here are some of their most important uses:

1. Oil and Gas Sector

In the oil and gas industry, level transmitters monitor levels in pipelines, separators, and tanks, ensuring the safe and efficient transport of oil and gas.

2. Water Treatment

Level transmitters help control water levels in reservoirs, tanks, and wastewater treatment plants, preventing overflow and maintaining proper water balance.

3. Food and Beverage

In the food and beverage industry, level transmitters ensure accurate measurement of liquids and solids, maintaining consistency in product quality.

4. Chemical Processing

Level transmitters are crucial for measuring and managing the levels of reactive and corrosive chemicals, ensuring safe handling and accurate dosing.

5. Pharmaceutical Industry

They help maintain precise levels of liquids in mixing and storage tanks, essential for quality control and compliance with regulatory standards.

How to Choose the Right Level Transmitter

Choosing the right level transmitter involves considering the specific requirements of your application. Here are key factors to keep in mind:

1. Measurement Medium

Determine whether you need to measure the level of liquids, solids, or gases. Each type of level transmitter has its strengths, depending on the material being measured.

2. Accuracy Requirements

Some processes require high-precision measurements, while others may tolerate slight deviations. Radar level transmitters are known for their high accuracy in complex environments.

3. Installation Environment

Consider factors such as temperature, pressure, and the presence of dust, vapours, or chemicals. Ultrasonic level transmitters are great for non-contact measurements in harsh conditions.

4. Maintenance Needs

Some level transmitters require regular maintenance, while others are more maintenance-free. Capacitance level transmitters are generally low-maintenance and easy to clean.

Conclusion

Level transmitters are fundamental devices for maintaining control and efficiency in various industrial processes. Understanding the different types of level transmitters and their applications can help you select the best fit for your needs, ensuring accurate measurements and reliable performance. Whether managing water treatment, chemical processing, or any other fluid-handling application, the right level transmitter can make a significant difference.