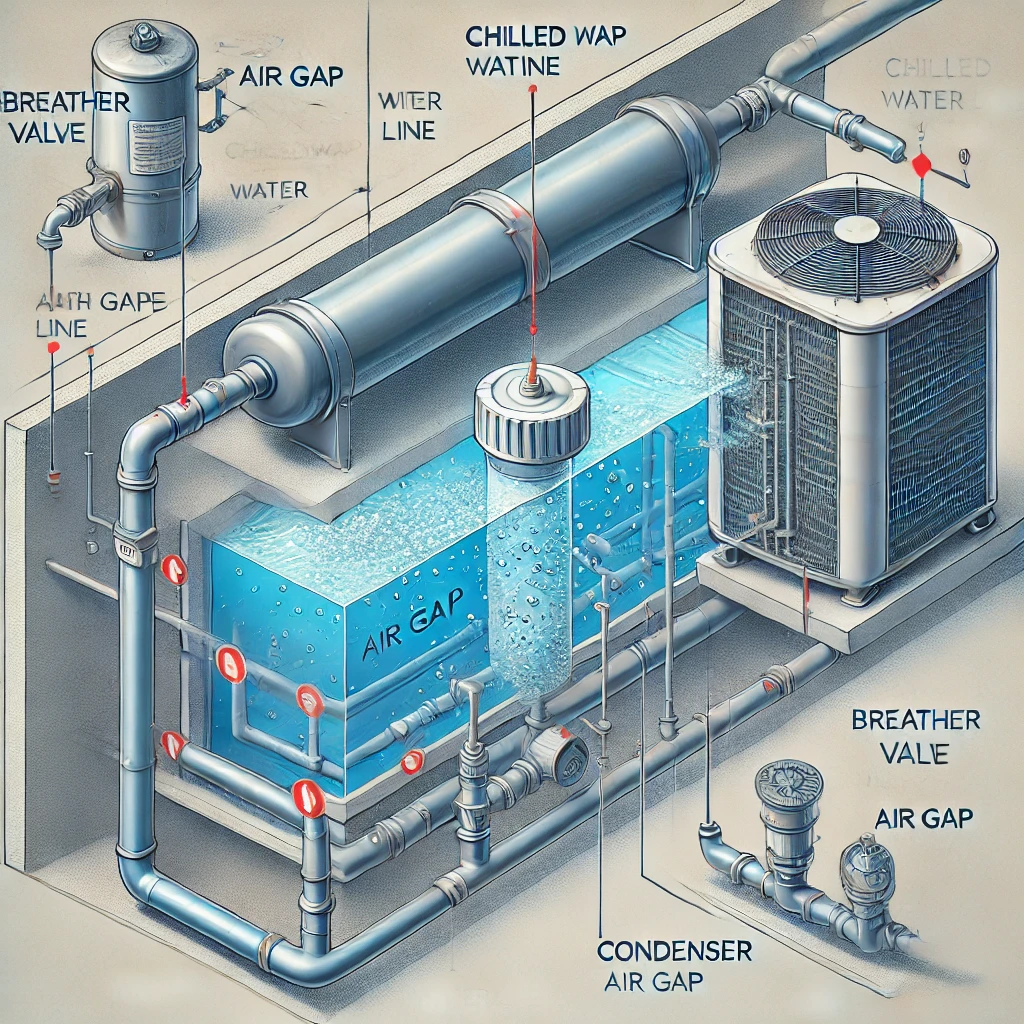

Case Study: Resolving Air Gap in a Chilled Water Line to a Condenser Using a Breather Valve

Breather Valve:

A breather valve is a device used to release trapped air or gases from a system, ensuring smooth fluid flow. In cooling systems like chilled water lines, it prevents air pockets that can disrupt performance and efficiency.

Background

A major industrial client was experiencing operational inefficiencies in their HVAC system due to an air gap in the chilled water line leading to the condenser. The air gap was causing flow interruptions, resulting in reduced cooling efficiency and potential damage to the equipment due to inconsistent water flow and pressure.

Challenge

The primary challenge was to eliminate the air gap in the chilled water line without causing additional pressure drop or introducing any contamination into the system. Traditional methods, such as manual venting, were not feasible due to the constant monitoring and maintenance required.

Solution: Breather Valve Implementation

To address the issue, a breather valve was selected for its ability to automatically vent trapped air from the chilled water line, ensuring smooth and continuous flow to the condenser. The breather valve was installed at a strategic high point in the pipeline, where air pockets were most likely to accumulate.

Implementation Process

- Site Analysis: The system was thoroughly analyzed to identify the optimal location for the breather valve installation. This involved monitoring the chilled water line during operation to determine where air pockets formed most frequently.

- Valve Selection: A breather valve was chosen based on its compatibility with the existing chilled water system. The valve was selected to handle the specific flow rates and pressure ranges of the system, ensuring it could efficiently vent air without compromising the line’s integrity.

- Installation: The breather valve was installed at the identified high point in the chilled water line. The installation process included minor modifications to the pipeline to accommodate the valve and ensure a secure fit.

- Testing and Monitoring: After installation, the system was tested to ensure the breather valve was functioning correctly. This involved monitoring the flow rate, pressure, and temperature of the chilled water line to confirm that the air gap had been effectively eliminated.

Results

The implementation of the breather valve successfully resolved the air gap issue, resulting in the following improvements:

- Enhanced Cooling Efficiency: The elimination of air pockets led to a more consistent flow of chilled water to the condenser, improving the overall efficiency of the HVAC system.

- Reduced Maintenance Costs: The automatic operation of the breather valve reduced the need for manual venting and monitoring, leading to lower maintenance costs.

- Improved Equipment Longevity: By ensuring a consistent flow of chilled water, the risk of damage to the condenser and other associated equipment was significantly reduced.

Conclusion

The strategic use of a breather valve provided an effective solution to the air gap problem in the chilled water line, enhancing the performance and reliability of the HVAC system. This case highlights the importance of selecting the right components and understanding the specific needs of the system to achieve optimal results.